good-touch

good-touch

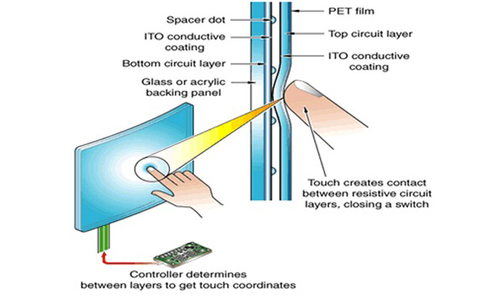

5-Wire resistive touch technology can be used in various applications and environments. The Analog Resistive touchscreen is a sensor consisting of two opposing layers, each coated with a transparent resistive material called indium tin oxide (ITO). The ITO has a typical sheet resistivity between 100 and 500 ohms per square. The layers are separated by a pattern of very small transparent insulating dots. Silver ink bus bars (~50mW/sq) make an electrical connection to the surface of the ITO at the outside edges, spanning the desired axis of the given layer. Silver ink traces (~50mW/sq) connect the bus bars to an electromechanical connector used for interfacing to the sensor. The cover sheet has a hard, durable coating on the outer side, and a conductive coating on the inner side. When touched, the conductive coating makes electrical contact with the coating on the glass, and a touch is registered by the analog controller.

Resistive touchscreens deliver cost-effective, consistent and durable performance in environments where equipment must stand up to contaminants and liquids, such as in restaurants, factories, and hospitals. Disadvantages of Resistive technology include only 75% optical transparency and the fact that a sharp object can damage the resistive layers.